Professional Restoration

Artisan Fidelity restoration services involve individual factory model disassembly, frame-off rebuilding, refinishing and comprehensive refurbishing by hand. Each model treated with the same close attention to detail including deep ultra sonic cleaning, original equipment manufacturer specified lubricant, degausing and hand polishing. Intricate parts disassembly, primary bushing inspection, replacement, bearing housing flush, spindle micro polishing, heat removal and fresh vacuum oiling of main sintered bronze bushings. Manufacturer viscosity specific bearing oil is used to maintain the highest standard of operation and lowest friction, however, in certain cases modern synthetic spindle oil may be substituted. Certain proprietary designed upgraded precision machined parts possessing ultra high tolerances which meet or in many cases, exceed original equipment manufacturer standards available for all makes and model turntables serviced. Electronics and motors, including power supplies and control, logic and drive boards bench tested then painstakingly rebuilt by renowned electronics engineer and open reel tape machine expert Soren Wittrup / CS Electronics, a lifelong professional proudly endorsed by recording industry legend John Klett. Hand selected, audio grade capacitors and premium Silver based Cardas solder routinely employed. Preliminary and post service oscilloscope bench inspection of internals comprehensively carried out to ensure proper electrical and mechanical functioning. Controller, contacts and power switches are striped and cleaned using electrical specific lubricants.

Garrard 301 restoration Schedule I Grease Bearing & Schedule II Oil bearing

Garrard 401 restorati0n

Limited 2 year Warranty

Brand new Replacement factory oem type Idler wheel with new rubber outer periphery.

Brand new 60Hz / 50Hz Brass Motor pulley.

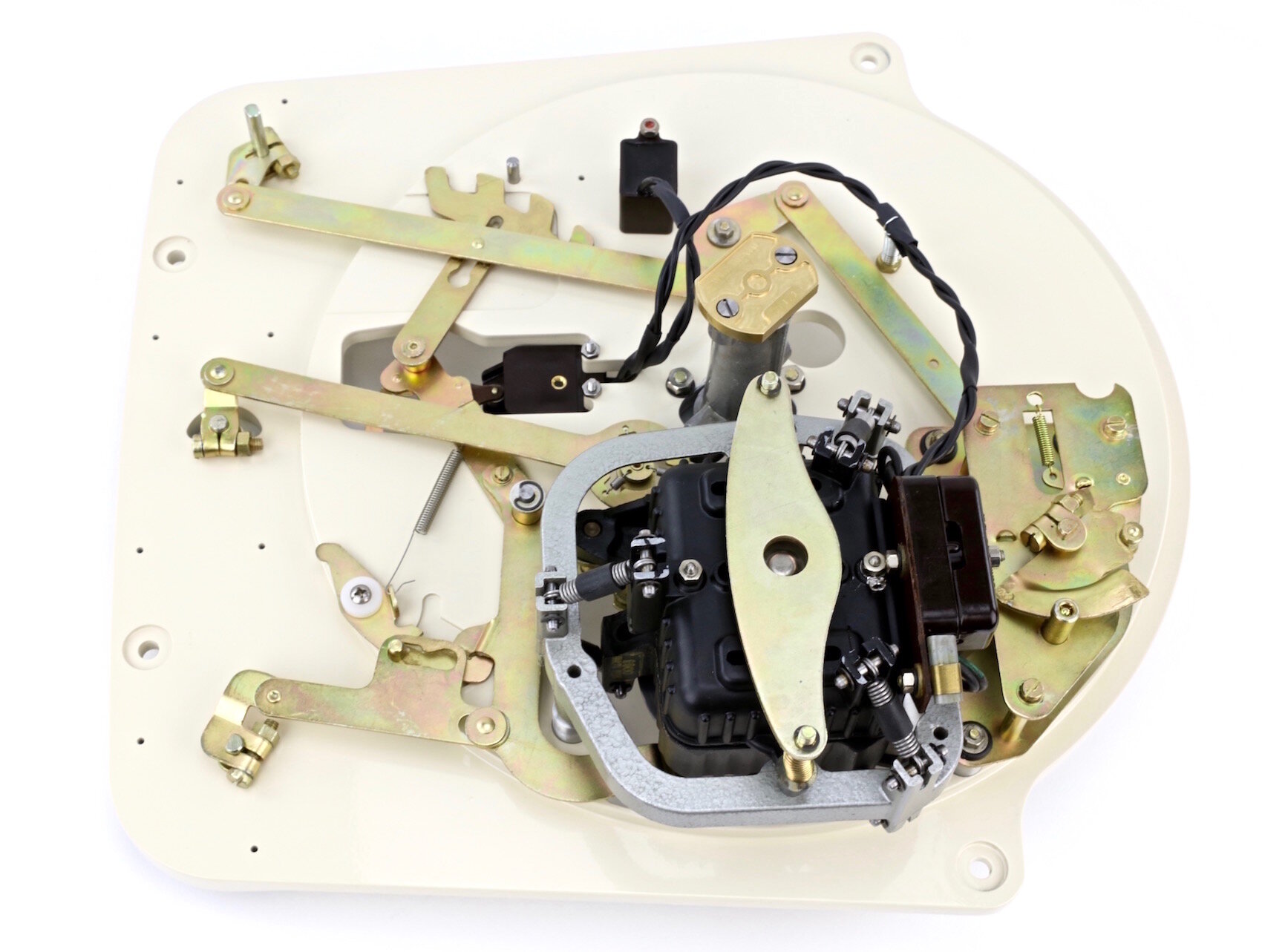

Motor restoration including realignment, sintered bronze bushing fresh oil charge and dual coil resistance scope check by certified electronics bench technician. (Note: custom wound primary ac motor coils optional.)

AC induction motor drive shaft inspection, surface micro polish and squirrel cage rotor test.

Motor carriage upper and lower suspension springs and rubber spring damper replacement.

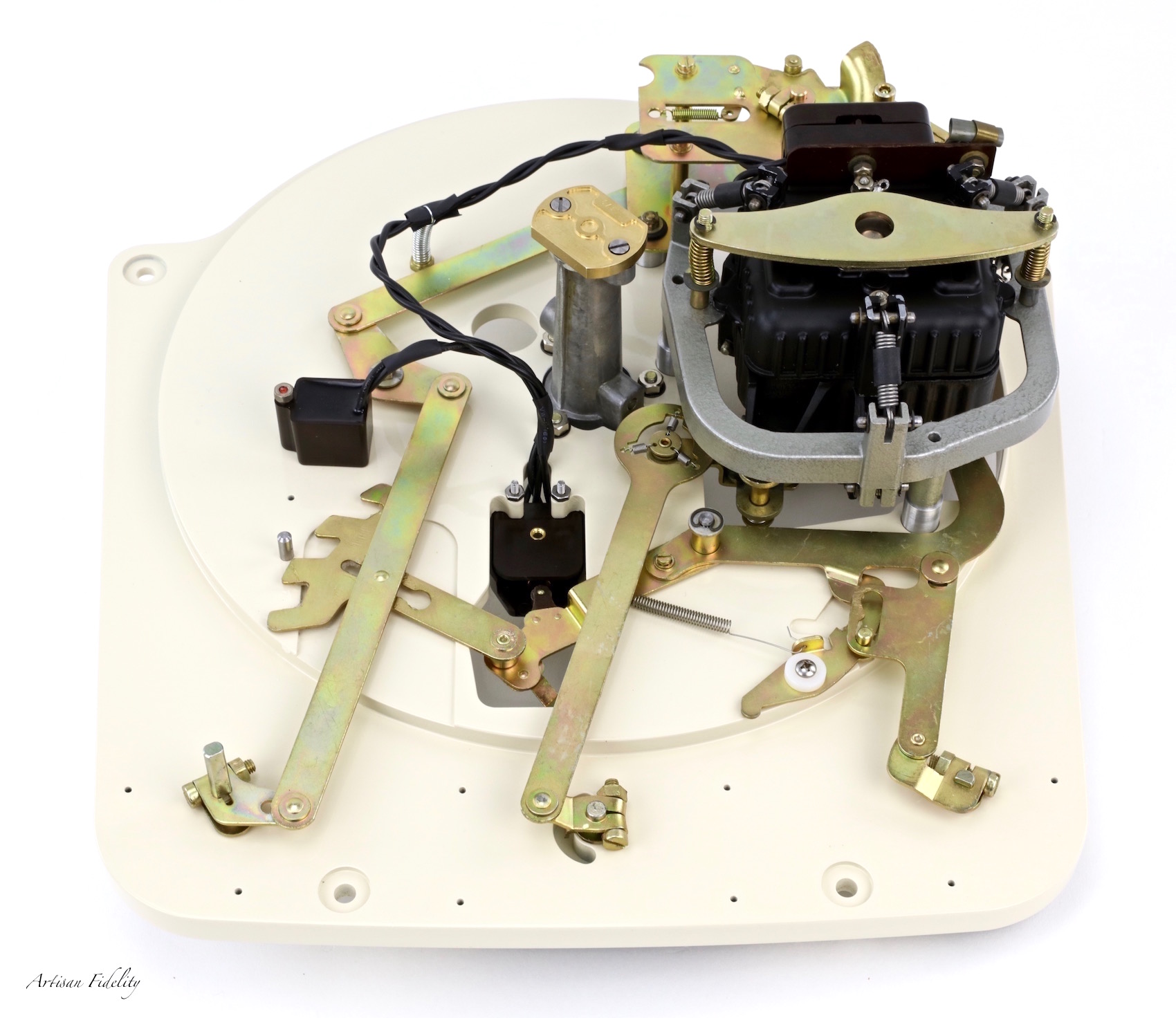

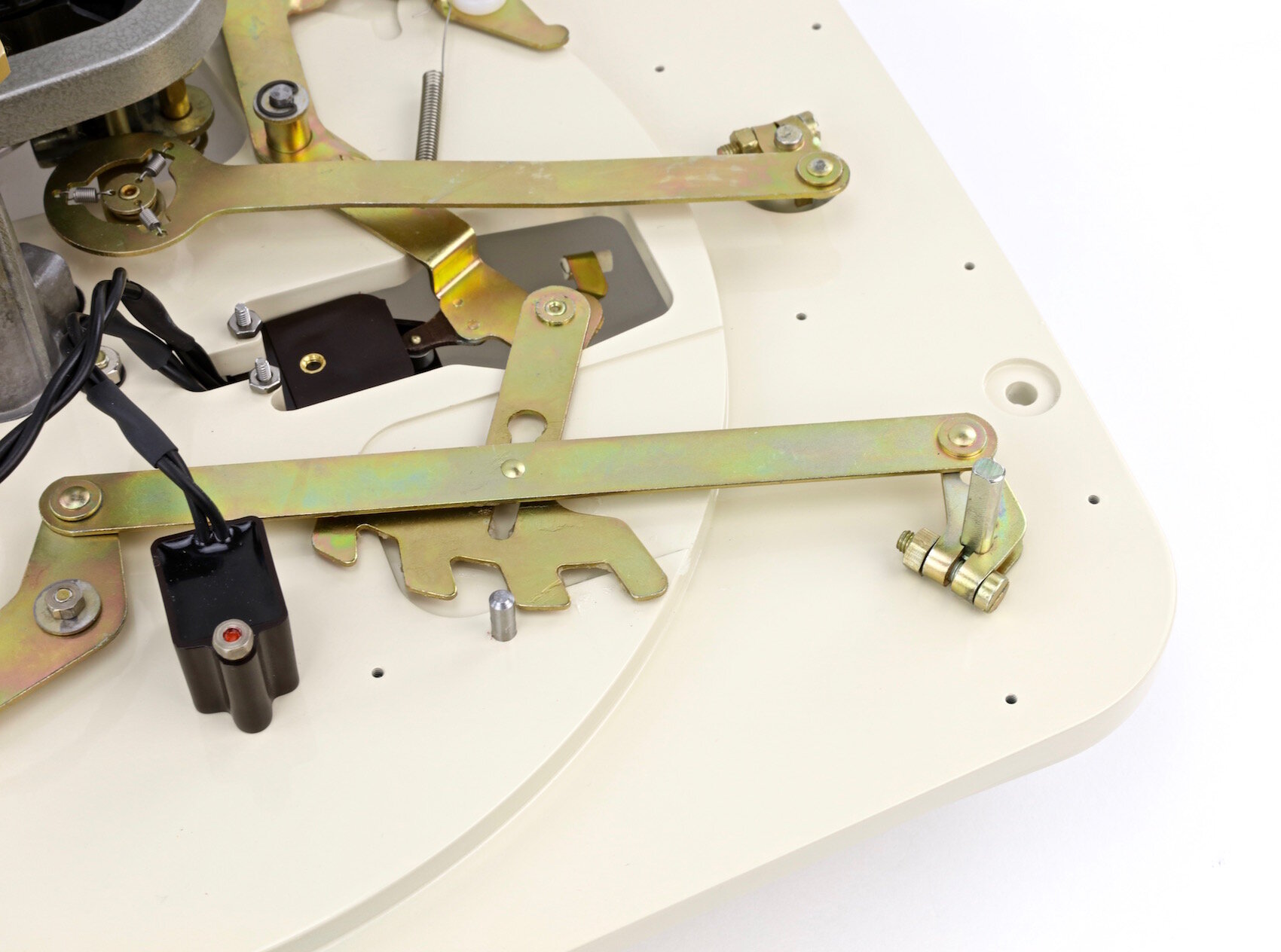

Comprehensive frame off parts restoration, re-lubrication, grease and alignment.

Ultra sonic deep cleaning of linkage components plus spring soak.

Professional Zinc electroplating coating application for linkage parts.

Contact cleanse, polish and treatment of electrical contacts.

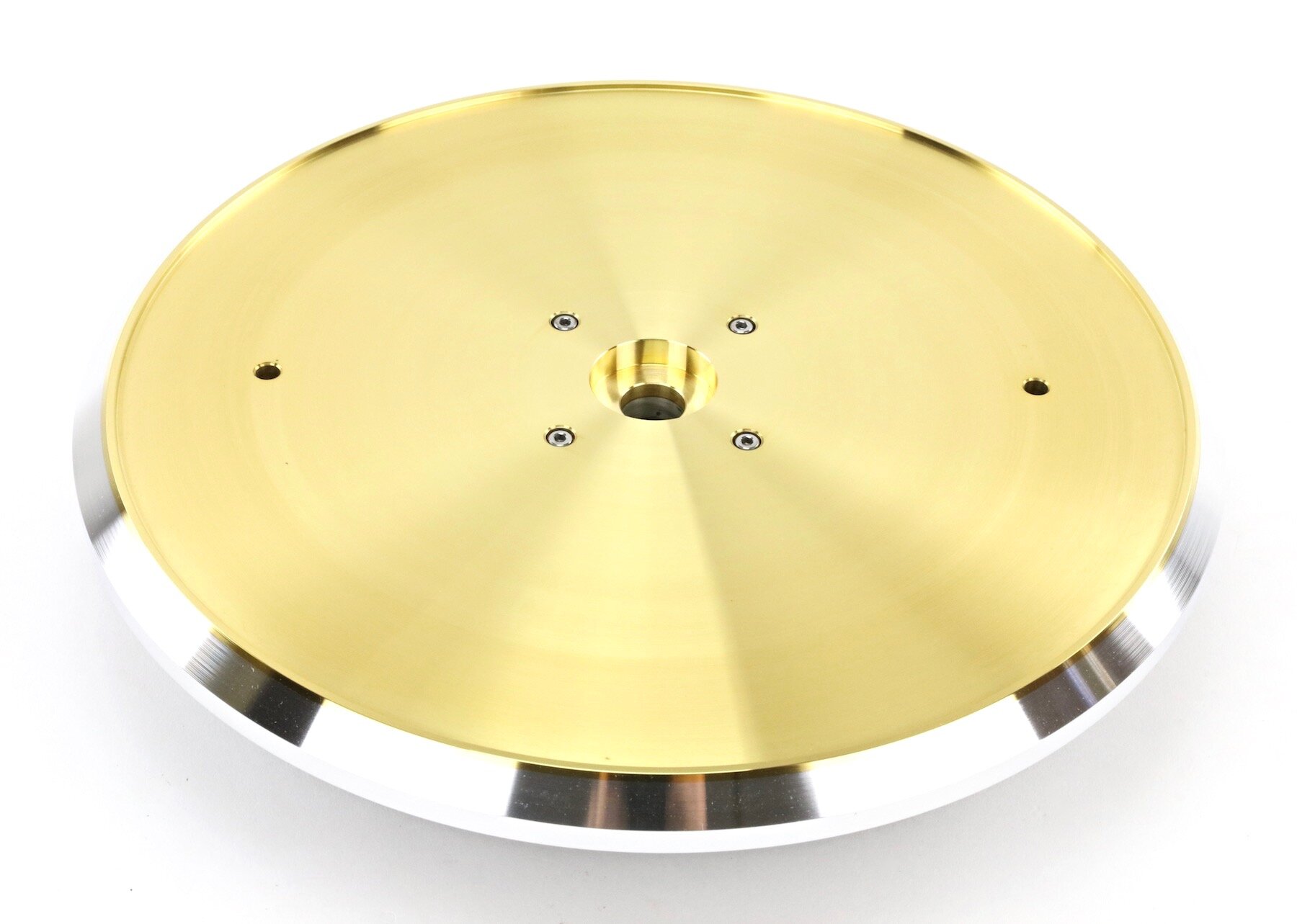

Hydrodynamic Oil Bearing / Grease Bearing cavity main housing flush, cleanse, ultra sonic treatment, main bearing journal micro polish, fresh synthetic grease/oil sintered bronze bushing re-charged and lower gasket replacement.

Idler wheel carriage assembly upper and lower sintered bronze bushing oil cleanse, vacuum re-charge with fresh oil and brand new replacement spark suppressor module.

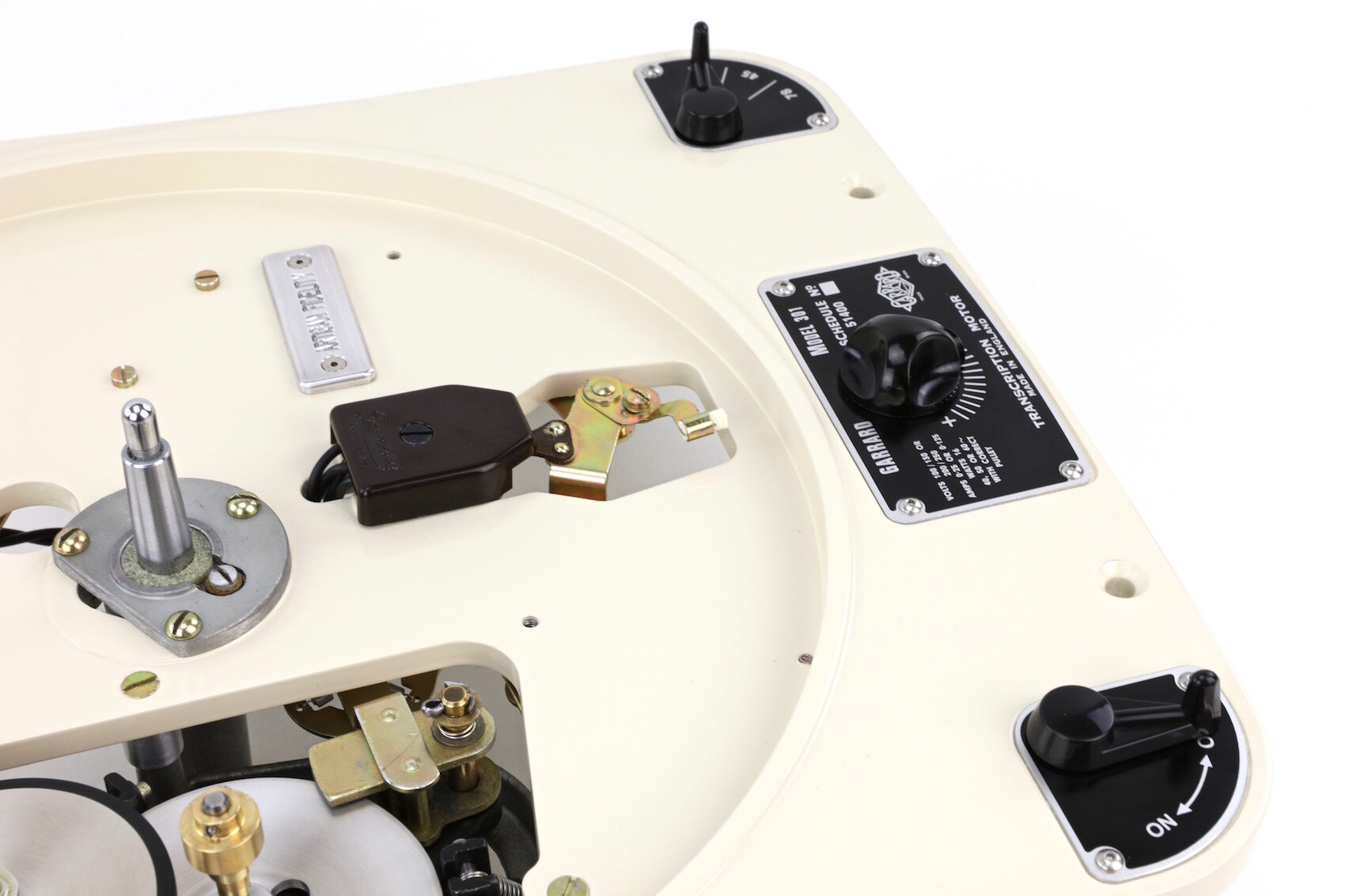

Brand New or refurbished vintage factory Speed control and On/Off switches.

Brand New or refurbished Factory Type Garrard 301 Controller Plates and rivets.

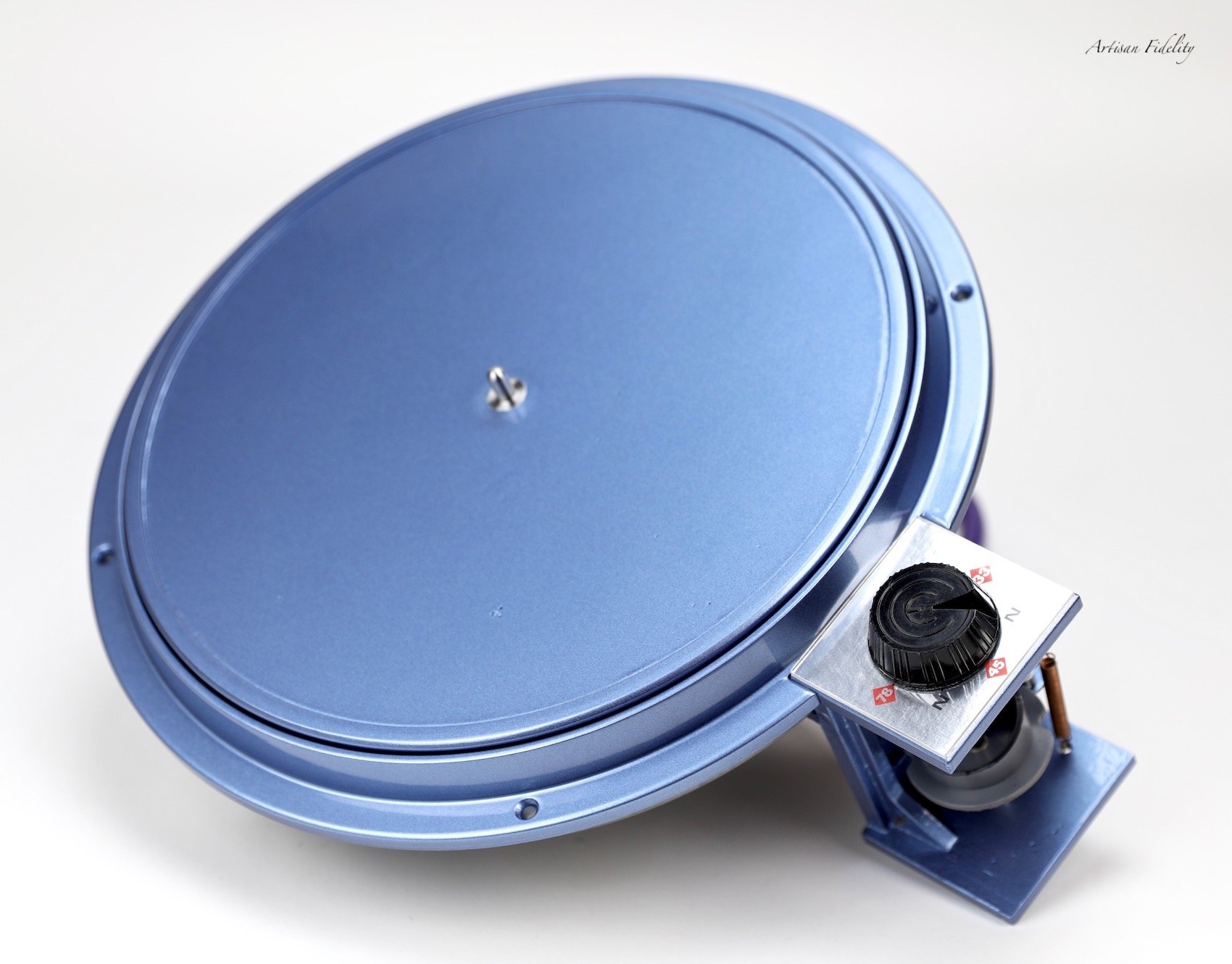

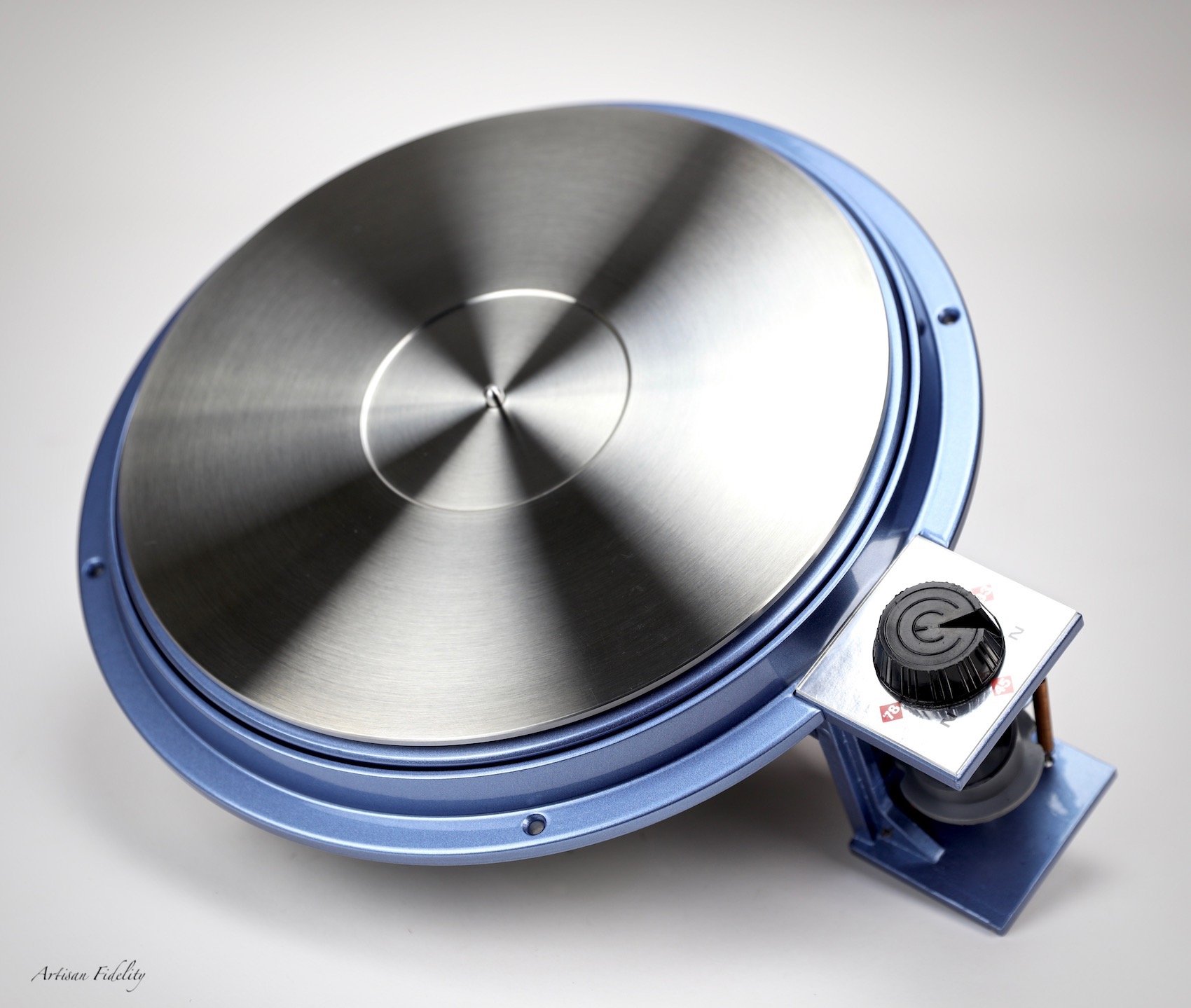

Sand blasted, striped, professionally re-sprayed painted main chassis plate with ultra premium factory automotive paint color or factory Garrard Hammertone color finish.

Resurfaced professionally re-painted Black Garrard factory aluminum platter with strobe markings, when applicable.

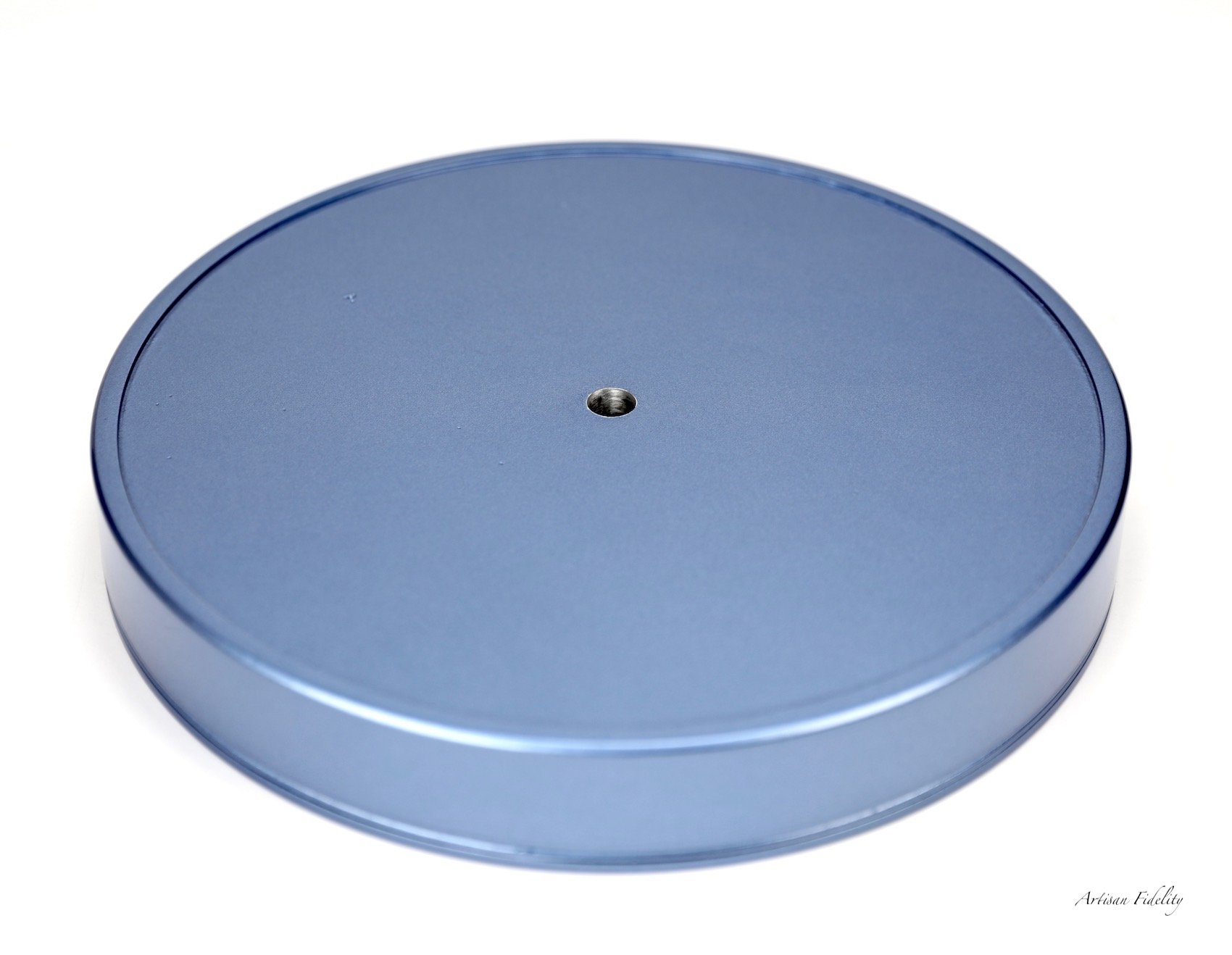

Polished factory Garrard eddy current brake disc.

Brand New Copper AC power cord.

Brand New or Factory refurbished rubber platter mat with Garrard factory logo.

48 Hour run-in

Thorens TD124 restoration

Comprehensive Frame Off Restoration and Motor Service includes initial instrument diagnosis and mechanical operation check.

Thorens factory linkage inspection, strip & ultra sonic cleanse, full re-lubrication and metal corrosion inhibitor application.

Brand new replacement Thorens factory oem type rubber auxiliary flywheel drive belt.

Thorens E50 motor upper and lower receiver sintered bronze oil bushing replacement and felt oil washer replacement.

Thorens E50 induction motor drive shaft inspection, micro surface polish, replacement of worn factory 2mm ball bearing tip with brand new precision lab grade ceramic ball bearing.

Suspension damping kit.

Main bearing journal and bearing housing service including cavity flush, upper and lower sintered Bronze oil bushing replacement sleeves with premium low viscosity close tolerance hydrodynamic bearing specific oil and shaft micro polish.

Lower bearing housing thrust cap service.

Factory Idler Wheel periphery rubber surface clean and replenish service.

The following new replacement parts and services available: main chassis professional ultra premium professional automotive paint, new Plexi strobe window, new identification badges, Thorens oem type idler wheel, new Thorens rubber mushroom set, Thorens factory sticker, new switch compressor condenser, replacement primary E50 motor coils and upgraded lower main bearing housing brass thrust plate with copolymer thrust pad, MkI to MkII E50 motor stainless steel suspension cradle conversion, and Hanze HiFi Thorens TD124 motor suspension spring set optional.

Technics Sp10mk3 restoration

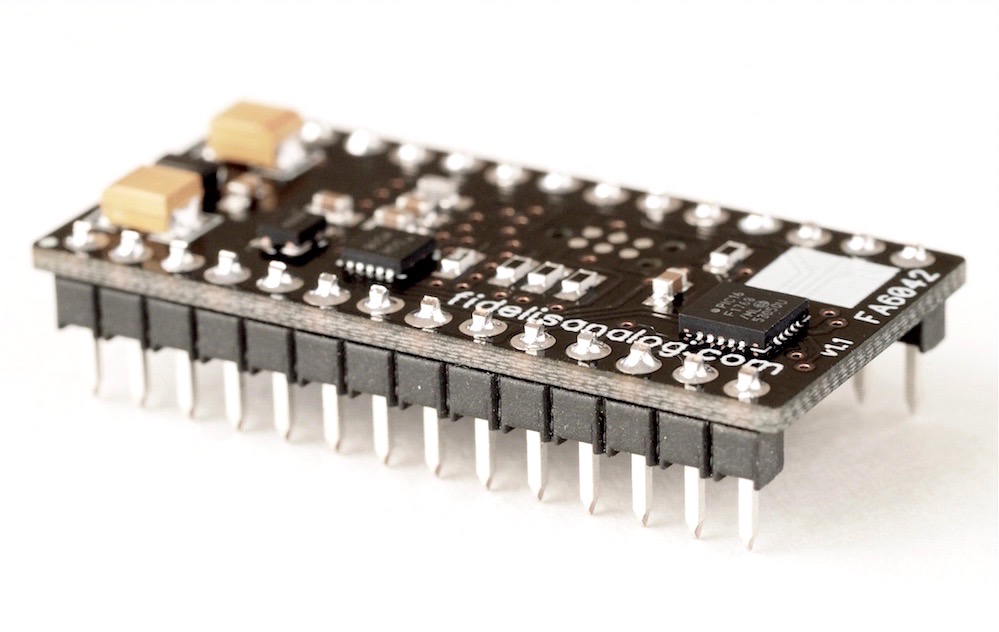

Base line test and evaluation, Phase tracking timing bench test, Frequency and reference oscillator motor level calibration, Master Clock Crystal and auxiliary main board inspection, PCB board cleanse, Power supply voltage + rails adjusted and scope checked, Electrolytic capacitor + rectifier diode replacement, Motor driver transistor replacement, DC motor torque ripple diagnostic test, Individual solder point inspection under magnification, Contact cleanse and switch lubrication, Solenoid test + belt tension adjust or optional removal of factory brake mechanism, Panel switch assembly contacts all resistance tested and installation of Fidelis Analog MN6042 replacement IC chipset (note: optional). Main bearing cavity flush plus bushing leach, scope inspection and cleanse, Bearing shaft micro polished and cavity re-lubricated using low viscosity, high grade hydrodynamic bearing oil, ultra low coefficient of friction advanced thermoplastic bearing thrust pad replacement and balanced main platter factory polishing service included. Post restoration ~ 72 hour run-in, evaluation and testing time.

Note: Replacement NOS factory Technics MN6042 (IC) chip sets reserved for clients only and covered under limited Artisan Fidelity manufacturers warranty, not available separately for individual resale purposes. Brand new replacement MN6042 chips manufactured by Fidelis Analog.

Australian Commonwealth Electronics 12D 3/4 Idler Drive Model Comprehensive Frame-off Mechanical Restoration, Solenoid and AC Motor Diagnostic Testing Service.