Technics Sp10Mk3

Technics Sp10Mk3

A brief history...

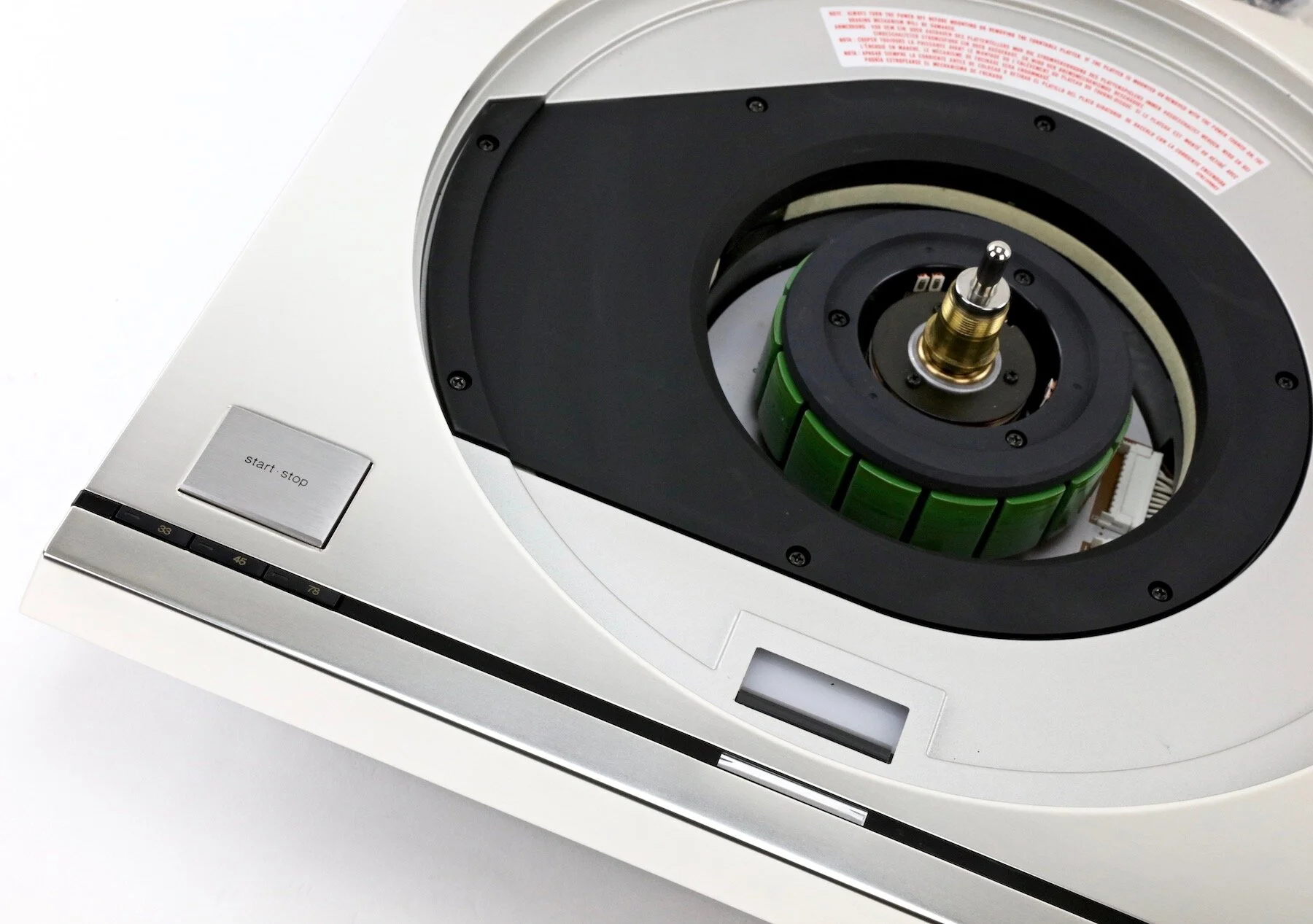

During the 1970's and early to mid 80's direct drive turntables were quite common amongst audiophile circles. These analog playback devices were used and enjoyed by recording studios, novice and well seasoned audio aficionados. Few however, achieved legendary status like the Technics SP10 series direct drive transcription turntables. From the first series SP10 on to the vastly improved MKII and finally the rare and quite desirable MKIII version, these turntables were legendary both in engineering prowess and performance. Eventually, after Technics had successfully introduced their first generation SP10 design and was garnering positive feedback from both end users and the audio press, they realized it was time to up the ante so to speak and return to the engineering table. The task at hand, to work on a new design, with lower rumble and better speed control. The result was a state-of-the-art assault on direct drive technology, the SP10 MKII. Some years after the completion of the final MKII model versions, came the ultimate and final version of the venerable SP10 called simply the MKIII. The Technics Sp10Mk3 internal mechanical assembly is based directly on the Technics SP-02M cutting lathe.

Quoted Technics factory database: "Starting torque of this ultra-low speed brushless DC motor allows a 16kg/cm spec - twice as much as that of the 1975 SP-10MK2 and roughly sixteen times as much as the original 1969 SP-10! This means a full speed ahead in 30° of a full rotation or 0,25s. The inertia moment of the 10kg platter is of 1,1 ton/cm2. The platter has a 1,5cm copper alloy core (inner platter), supported by a diecast aluminium outer platter. 1,1 ton/cm2 is, btw, the equivalent of 1000 tonearms all tracking at 2g. The power supply houses a very beefy and resin cast transformer and the speed and start/stop controls plus the ± 9,9% pitch control in 0,1% steps (outside).

Aesthetic inspiration derived from the vintage Technics SH-10B3/B5/B7 Obsidian plinth style is evident. These similarities are the extent of our designs shared likeness, as unfortunately for the vintage factory plinth, its overall sonic signature was a tremendous disappointment. As a direct result, Technics original design was received in a luke warm fashion by review publications and many users of that era. A vital key to a properly executed MkIII starts with a directly coupled plinth of substantial mass. Carefully tuned by ear, our design utilizes internal constrained layer damping using German Panzerholz engineered wood, non-magnetic substrates and resin bonded layered kiln dried hardwoods together to achieve the highest fidelity along with a nearly voidless non resonant structure. The accumulation of an optimal internal structure, meticulous build quality and integral Stillpoints active vibration /isolation technology results in nothing less than extraordinary in terms of the sound absolute. We begin with the main bearing / motor housing, which are removed, cleaned, inspected, micro polished and then re lubricated. Primary motor coil windings are inspected for flaws and lastly, the entire brake assembly is modified to further reduce friction and drag on the motor and bearing. After the MkIII's main chassis and power supply have been carefully scope checked, we then meticulously bench test and rebuild the outboard Technics Quartz power supply/motor controller using top of the line Nichicon and Panasonic electrolytic capacitors. This ensures consistent speed stability and long life expectancy. Silver solder used by Cardas and WBT. Main logic and control boards are carefully measured and inspected by a certified bench technician for proper electrical functioning. Minimal residual main bearing noise is effectively eliminated through the implementation of Artisan Fidelity's shielded "Quiet Core" bearing drain system. For optimal effective isolation and resonant tuning Stillpoints technology is employed. Our plinths accommodate nine to twelve inch tonearms and may be built in single, dual and up to quad tonearm configurations

Post restoration, updates and after secure plinth coupling, this magnificent direct drive turntable will easily compete with the finest analog playback systems in the world. One of the few classic engineering marvels which remains a modern reference.

Features:

Phase tracking timing bench test

Frequency and reference oscillator motor level calibration

Master Clock Crystal and auxiliary main board inspection

Power supply voltage and rails adjusted and scope checked

Belt tension adjust or removal of factory brake mechanism completely

Bearing cavity flush, inspection and cleanse

Bearing shaft micro polished and relubricated

Technics SP10 MkIII factory specifications:

Motor: brushless DC motor, electronic rectification, quartz-controlled phase-locked servo circuit

Platter: 320mm, 10kg copper/aluminum

Speeds: 33, 45 and 78rpm

Pitch control: 20%

Starting torque: 16kg-cm

Build up time: 0.25s to 33rpm

Braking time: 0.3s from 33rpm

Speed fluctuation by load changes: 0% within 10kg-cm

Wow and flutter: 0.015% WRMS (JIS C5521)

Rumble: -92dB (IEC 98A weighted)

Dimensions: 369 x 113 x 369mm

Weight: 18kg (main chassis only)

System weight 150lbs.

Natural Zebrawood plank finish shown, various bespoke exotic hardwood and automotive paint finish options available.