Garrard 401 Statement

Garrard 401 Statement

Garrard 401 Statement by Artisan Fidelity

The design architecture in its modest beginning is based on a factory stock Garrard 401. These British developed idler drives were first introduced in late 1964 and successfully sold some 50,000 plus units during its 12 year production run. After a long successful production period, the enormously accomplished Garrard 301 officially retired, immediately thereafter, the Garrard 401 model circa 1965 - 1976 was announced as its replacement. What the Garrard model 401 model promised was an improvement over the classic 301 model while featuring a shielded, higher torque motor and tighter manufactured tolerances.

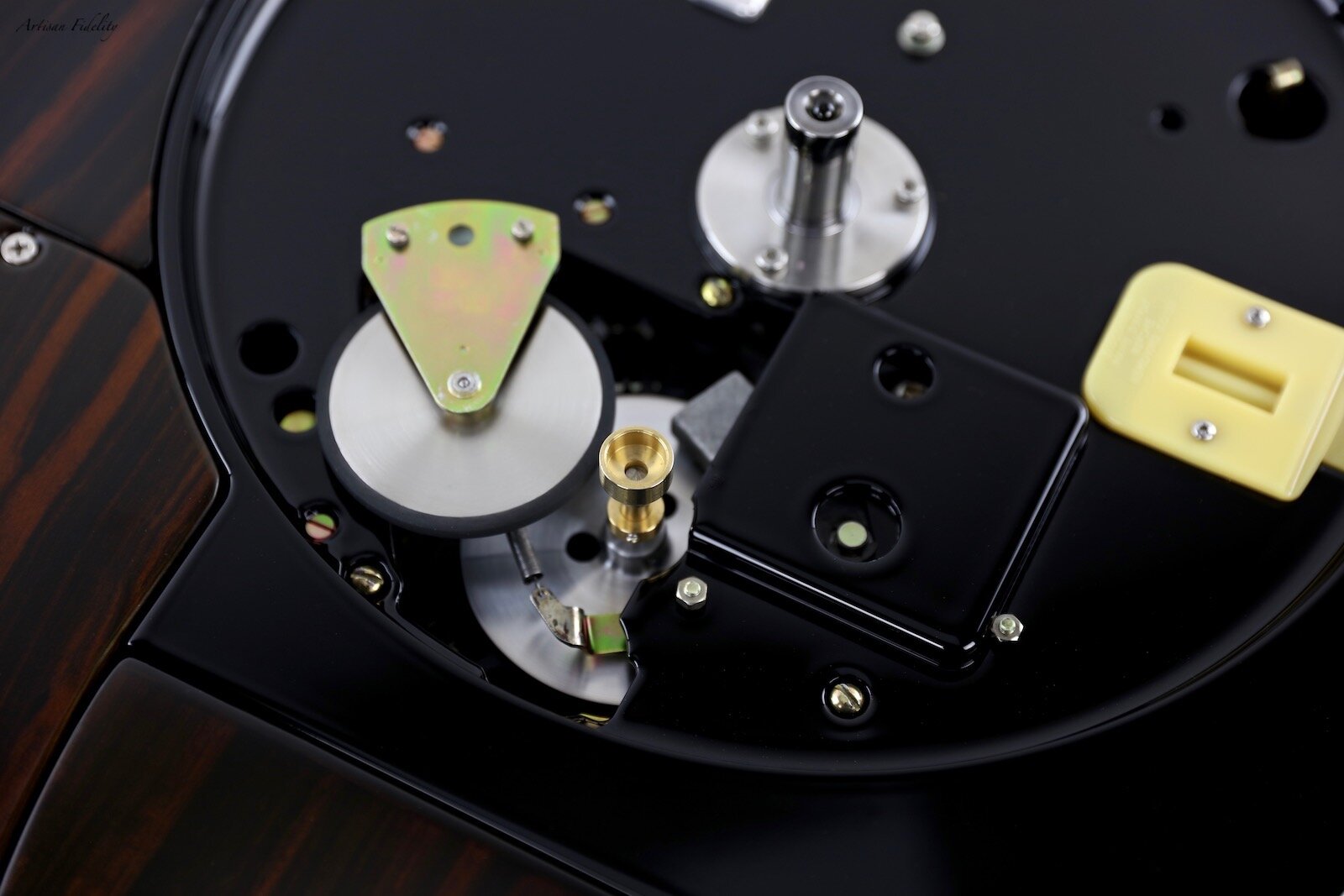

First, a donor model 401 is carefully selected, then begins the arduous task of a comprehensive restoration of all linkage, control switches, motor and bearing. Following the itemization of the parts removed, we begin the striping and deep ultra sonic cleaning process and main bearing disassembly/inspection. Factory motors are rebuilt, using refinished/restored internal bushings and re-aligned to factory specifications, then re-lubricated prior to final assembly. Stock factory idler wheels are replaced using modern machined high tolerance idler wheels featuring a special rubber composite outer rim with austenitic stainless steel hub and cnc ground center pin. Either 60Hz and 50Hz precision machined Brass motor spindles are supplied for international compatibility. All new replacement parts used in the rebuild are high tolerance precision machined components built to last a lifetime.

Designed strictly for the ultimate analog playback capability derived from the renowned English engineered classic idler drive platform. A fundamental approach in lowering center of gravity, achieving increased resolution in addition to drastic reductions in noise and friction is achievable through an inverted type bearing and tiered platter design. Modern echelon level analog playback front ends routinely feature such bearing topologies for these reasons. Additionally, the flywheel affect has been improved, as a result speed consistency throughout solidifies. Although our previous conventional Garrard 401 reference series bearing design was a radical departure and subsequent drastic improvement from stock offerings, the inverted bearing and modular platter design takes the resolution, noise floor and channel separation to a whole other level. Each set of inverted bearing and modular platters are cnc milled using solely state of the art milling machines, designed in collaboration with tribology and hydrodynamics consultants from Purdue University Department of Engineering.

Featuring the World’s First Inverted Modular Bearing and Platter based Architecture and solid billet aircraft Aluminum precision replacement heavy Garrard 401 chassis plate.

By employing a modular platter architecture, the user may contour the playback characteristics of the Garrard 401 Statement to a degree as each upper material selection will allow for a slightly different presentation. Material selections available: Copper alloy, Magnesium, 7075 Aluminum, Inox Stainless Steel. Please consult me directly for an explanation of unique playback differences between the various alloy selections.

During the 9 + year production cycle of the English Garrard 401 Transcription turntable, the company once again opted to employ a variable cast type aluminum based alloy primary chassis plate with undesirable structural coves and recesses. From the manufactures standpoint, this design proved both a cost effective and fairly consistent part to reproduce in quantity. However, using a plain variable casting process such as this means certain structural inconsistencies are simply unavoidable. Over time, these chassis plates may exhibit structural cracking and were known for notorious inconsistencies, primary weak spots in many cases resulting in severe degradation of playback. To remedy this critical engineering weakness and design compromise, we have developed a state-of-the-art heat treated, solid aircraft aluminum alloy based chassis plate possessing tremendous structural rigidity, zero internal structural voids and ultra high precision measured tolerances (v.2). To accompany the improved billet chassis plates, we have designed proprietary motor mounts and ancillary control linkage parts, tested and tuned for optimal playback characteristics and integrity. The superior audible playback characteristics gained through the precision chassis plates results in clarity never before imagined with this legendary transcription design.

Garrard 401 Statement Chassis Plate CNC Production Video (Link)

Elimination of stock factory Garrard idler wheel constitutes another engineered design model enhancement. We have developed a state of the art, precision cnc machined austenitic steel idler wheel with cnc ground center pin measuring zero run-out, physical surface running edge consists of a molded rubber composite. The diameter of the Statement idler wheel matched factory English Garrard specifications to within "0.002. The result translates immediately during first listen, increased clarity, focus and inner resolution across the audible frequency spectrum. In addition to a modern idler wheel design, we have also opted to replace the factory motor spindle pulley with precision cnc machined Marine Brass and Austentic Steel motor pulley variants. Again, through the application of computer aided design, drafting and automation in conjunction with superior metal alloy selections, we were able to achieve superior playback results over stock pulleys. The Garrard 401 Statement models additionally feature state of the art, cnc machined Eddy Current Brake Discs fabricated from a solid billet of heat treated, aircraft grade 6061-T651 aluminum. The precision tolerances allow a sheer, slip fit over existing factory Garrard 401 motor spindles with no additional slop, or play. The design ensures accuracy during playback, minimizing any residual wobble and consequential vibrations from propagating through the flywheel, motor and mechanical facilities.

Instrument net weight 34kgs. ~ 74lbs / 35kgs. ~ 78lbs.

Using solely the fundamental mechanical design architecture and re engineering a classic transcription turntable like the Garrard 401 requires extraordinary skill, dedication, painstaking attention to details and a level of passion few will ever realize. Our level of commitment is unsurpassed in the area of transforming classic analog playback instruments which have easily stood the test of time into analog record playback devices for the modern era designed to perform at a reference level, in any arena. A small, highly skilled and dedicated team of mechanical engineers, master woodworkers, designers, finishers, visionaries and artisans are who we are, producing the worlds finest modern classics, hand crafted, individually tuned by ear and precision engineered to last a lifetime. The word masterpiece truly defines the quality and musicality of our reference Garrard plinth, which is a feast for both the eyes and the ears. After extensive Garrard 401 plinth prototyping phases, we arrived at the place we are today which once not far in the past, was only several hand drawn sketches, a concept and a dream. Our small, highly skilled team of third generation master woodworkers, precision machinists and my own individual creative design concepts made the dream possible and the results, well, the results are nothing short of magnificent.

Individually hand and precision machined analog playback masterpieces